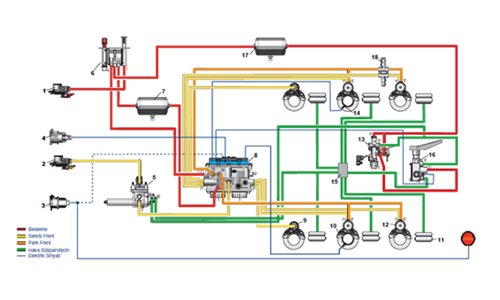

Havalı Fren SistemiPneumatic Braking System

Pneumatic Braking System

With the help of the air compressor working with the power of the motor, with the pressure applied by pressing the brake pedal; the brake system which performs the stop by converting this compressed air into mechanical power is called " Pneumatic Braking System". Since the force applied to the brake pedal can not be transferred to the vehicle wheels on heavy vehicles such as Buses, Trucks, Tractor Trailers, the air travels to the vehicle wheels and generates mechanical movement with pneumatic force before acting on the drum or brake disk.

Elements of the system

Air Compressor

It is the device that supplies the necessary air to the system with the power it receives. The air is transferred to the system by pressing the brake pedal.

Brake Pedal Valve

It is the valve that initiates the brake event, transfers the command from the pedal to the system, and is usually integrated with the pedal. In air brake systems, in general, the operating principle of the brake pedal valves is to transfer the pressurized pneumatic energy which is obtained when the driver pedals, to the tires.

Release Valve

A regulating valve, also called a regulator valve, is a valve that is used to evacuate air remaining in the brake pipes after braking in the system. In recent years, this valve has been integrated into the air dryer valve which extends the life of the system by drying the air in the system. In the latest technological systems, this product is part of the "Distrubutor integrated air processing unit", which combines the functions of dryer filter-drain and distributor.

Distributor Valve

It is the valve which is used to distribute the appropriate air pressure from the compressor to the tyres with brake command from brake pedal. It enters through the air supply inlet and exits through the delivery holes with the relevant bars. In the latest technology, this apparatus is integrated with the Drying Valve (Air Processing Unit) on the Discharge Valve.

Hand Brake Valve

The handbrake provides the brake by directing air directly to the tire regardless of the general braking system. However, it is still working with the air.

Trailer Control Valve

It is the valve which commands the braking system of the trailer connected to the rear, in the trailer trucks, vehicles which are used to pull trailers.

Relay Valve

These are the valves that fuction to compansate pressure value imbalances in the air line of the brake system. These valves increase, reduce and distribute the pressure of air according to the conditions. The relay performs the task.

Boots And Spring Brake Chambers

These are mechanisms that enable the compressed air from the air compressor to be turned into a mechanical power to affect the brake disc or the drum. Logically it consists of two air chambers connected to each other by a piston.

The air that is filled in one of the chambers pushes the piston and the shaft connected to the other chamber moves, it the converts vertical movement to horizontal, and the brake lining is expanded. The brake lining rubs against the disc or the drum, and the brake occurs.

Load Adjustment Valves

Taking into account the weight of the right and left side of the total load on the vehicle, it decides how much air should be released to which tyre and prevents it from overturning. Thanks to a tool attached to the vehicle's body, it works independently from the driver.

31.08.2018